A second group of MultiCycle delegates were being brought face to face with the practicalities of achieving materials recovery in the end of life phase of motor vehicles, courtesy of a visit to GBP Metals Group’s Xàtiva facility.

The MultiCycle project held a successful kick-off meeting in Brussels on 28th November.

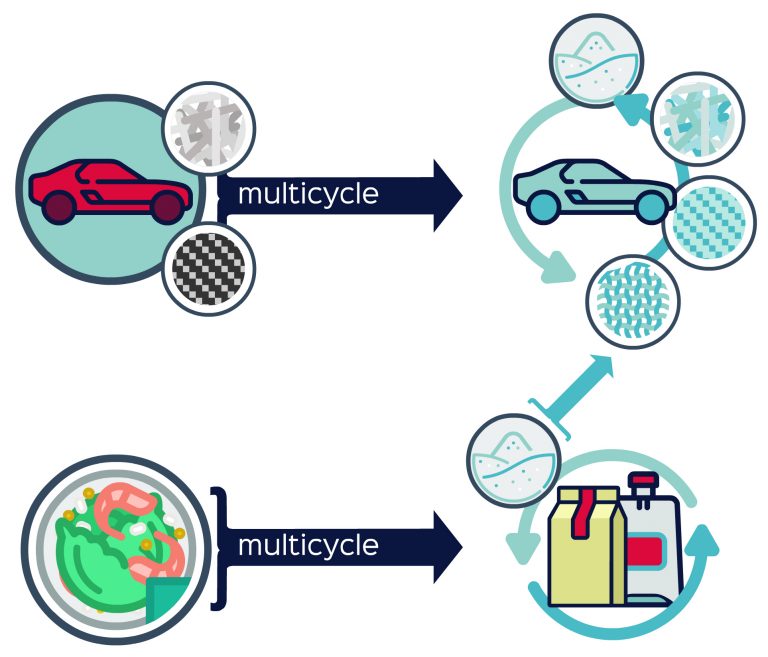

This new three-year EC Horizon 2020 Innovation Action will deliver an industrial recycling pilot plant for thermoplastic-based multi-materials allowing selective recovery of pure plastics and fibres from mixed wastes without downgrading as a key enabling step towards the realization of a circular plastics economy.

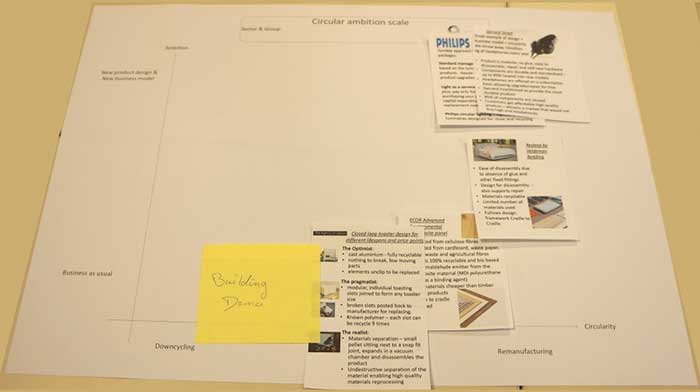

Creating circular value chains is not always straightforward, as choices for each stage have ripple effects on the entire chain. These effects can have secondary effects, and so the ripples go on. The only way to resolve this is to implement an iterative process.

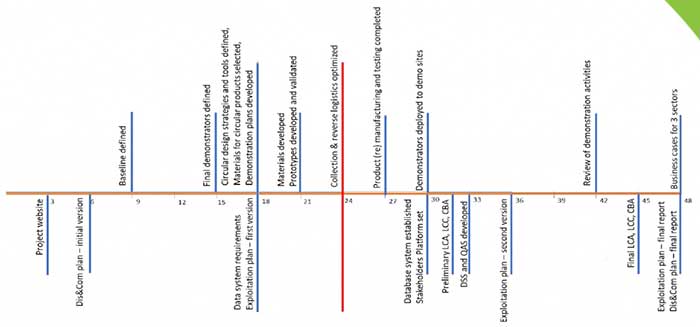

Partner ITENE hosted the month 18 meeting of the ECOBULK partners at their offices in Valencia, Spain. The partners participated in workshops and shared their progress. The meeting focused on refining the prototype designs, discussing material developments, and preparing for the demonstrations due to be deployed by the end of 2019.

The main aim of the meeting was to put all the pieces of the puzzle together for each of the planned demonstrations. Several exciting new concepts have been developed by the partners in the past 2 years which we expect will enable new highly circular materials and products to be produced.

Coventry is the traditional home of the British automotive industry. The industry reached its peak around 1950, when the UK was the second-largest car manufacturing country of the world. At this time there were 12 manufacturers in Coventry including then household names such as Rover, Jaguar and BMC (makers of the Mini) and it became known as the British Detroit

New partners Coventry and Warwick University hosted the month 24 meeting of the ECOBULK partners at Scarman Conference Center in Coventry, UK. The main focus was on finalising the plans and ambitions for the real-life demonstrations that are due to begin.

The Multicycle project’s six-month General Assembly meeting was an opportunity for partners to update collectively on progress made in the opening months of the project, and to build momentum behind the next steps towards up-scaling the CreaSolv® novel solvent-based process for recycling multi-materials packaging and composites.

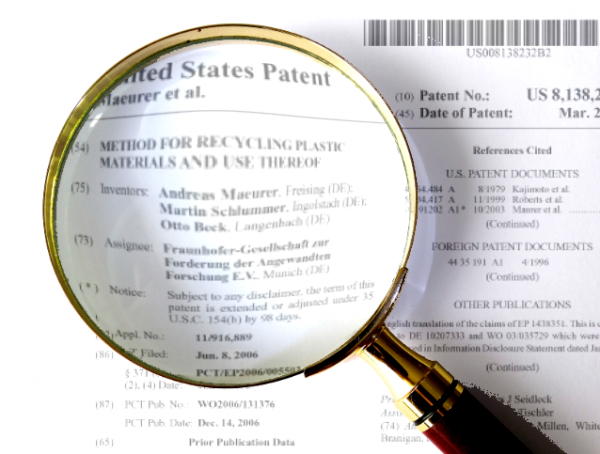

Work during the early months of the project has produced an up to date review of the technical and patent literature dealing with recycling processes for MultiCycle’s target multi-materials and established the specifications for the different processes involved in material recovery and reprocessing, providing an understand of the requirements of converters and end users in terms of properties, price etc. for the resulting secondary raw materials produced.

Technical work is well underway to obtain and evaluate a wide selection of waste material streams representing the variety of material types which the MultiCycle pilot plant might be expected to handle, and to identify from this a broad window of suitable waste stream requirements within which economic and practical processing could take place.

At this stage, the materials recovered from treated waste will be characterized with respect to their application in plastic packaging, textiles and composites. This will involve effort from across the consortium, but particularly Centexbel.

At the heart of MultiCycle is the engineering, installation and commissioning of a CreaSolv® pilot plant, and the demonstration of its performance under optimal operation. The pilot plant will handle both composites and multilayer packaging found in currently non-recycled plastic waste mixed streams, recovering high quality recycled polymers and polymer free fibres in good yield for re-use in high end applications.

MultiCycle is not just about demonstrating impressive new processing technology. Setting up the initial value chains, and raising industry acceptance and demand for more sustainable materials are also crucial to success, and this process begins with the demonstration of the potential of recovered materials in packaging and automotive applications.

The emerging MultiCycle proposition will be thoroughly evaluated, not just at at the technical level, but for its sustainability in development and implementation across the board.

In order to realise MultiCycle’s vision of leading the transition towards a sustainable post-petroleum society in the plastic sector and assist Europe in the transition towards a Circular Economy the consortium partners are working towards carefully planned post-project exploitation pathways.