Creating circular value chains is not always straightforward, as choices for each stage have ripple effects on the entire chain. These effects can have secondary effects, and so the ripples go on. The only way to resolve this is to implement an iterative process.

This iterative process has been integrated into the design process for the ECOBULK prototypes and demonstrators. Initial prototype designs were created based on the Circular Design Framework and workshops from the previous consortium meeting. The next iteration in the process were the business model workshops at the M18 meeting in Valencia.

Design Workshops – Optimizing Business Models

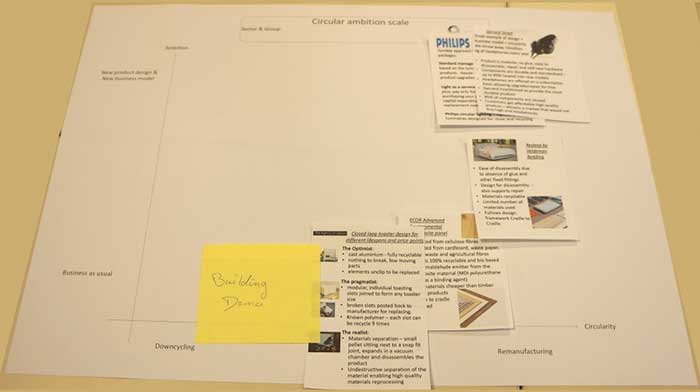

To start off with, the partners were asked to judge a number of different circular products and concepts that have been introduced into the market recently. Each of these was to be placed on two scales – one reflecting the level of circularity involved in the idea and another one assessing the level of ambition in the business model being used. The discussions served to calibrate the participants understanding and expectation of circular solutions and business models. After discussing several of these examples, the participants were then asked to consider the prototypes and demonstrations planned for ECOBULK.

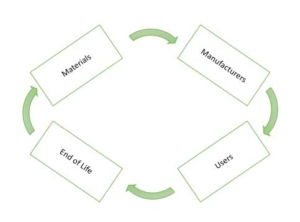

For this exercise the participants were divided into groups, each representing the different stakeholders in the system. There was a Materials table, a Manufacturing table, a Users table and an End-of-Life table. Each table was confronted with questions about what practical solutions or considerations would be important to increase the circularity of products in a particular sector.

For this exercise the participants were divided into groups, each representing the different stakeholders in the system. There was a Materials table, a Manufacturing table, a Users table and an End-of-Life table. Each table was confronted with questions about what practical solutions or considerations would be important to increase the circularity of products in a particular sector.

A list of requirements and questions would then emerge to could be directed to any of the other stakeholder tables. This list could then be passed around to the relevant stakeholders to answer and/or possibly provide further requests and questions to other tables. After several rounds, an overall shared picture could crystallize among the groups about the remaining obstacles and challenges that could be solved to improve the current circular concepts.

During the Construction workshop, some of the considerations revolved around the practicalities of separating waste streams for recovery, the importance of end-user behaviour in ensuring the availability of waste streams, and strategies for product life/cycle extension. For example, when trying to recover materials it is essential to have reliable data on what the material contents are, and it would be most helpful if materials were mixed as little possible, or at least were easily separable. To improve user attitudes and behaviour towards returning materials back into the cycle, communication was considered key – concepts like tagging materials with informative and inspiring messages like “in my next life I would like to be a spoon” to encourage people to be aware and engage with the life-cycles of their products. To solve for the collection logistical problem, the end-user engagement and strategies for life extension, a peer 2 peer network would allow end-users to match supply and demand in an organic way.

Slotted construction makes components easily separated for reuse and recovery.

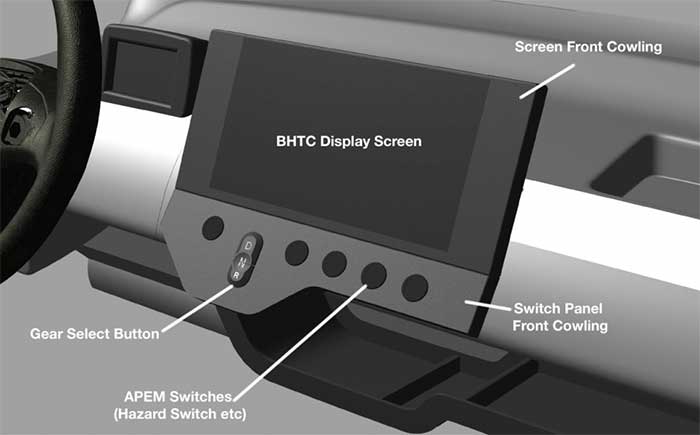

The Automotive workshop produced some interesting discussions about the use preferences of car drivers which may be a barrier to shared car models, a more modular approach to vehicle design, and the manufacturers role in creating a wider acceptance of recycled materials used in aesthetic components. The idea of car sharing is quite popular, but still lacks wider appeal possibly because there is no possible customisation of the shared vehicle. This can be difficult to accept for many users who have as much an emotional relationship with their cars as they do a functional one. More modularity in design and equipment could help to increase the life span and maintain value by exchanging outdated parts with modern ones. Acceptance of recycled materials in aesthetic components could also be improved by manufacturers adapting their marketing to promote them – users have already accepted other forms of upcycled and recycled products as fashionable.

Central console can be easily replaced and refurbished, extending the useful life of the car.

The partners will continue to develop and refine their prototypes as ECOBULK starts preparing for the demonstration phase of the project. Follow the progress by signing up for our newsletter, and join us on our social media channels.