Pilot Separation Process and Monitoring Systems

Technical work is well underway to obtain and evaluate a wide selection of waste material streams representing the variety of material types which the MultiCycle pilot plant might be expected to handle, and to identify from this a broad window of suitable waste stream requirements within which economic and practical processing could take place.

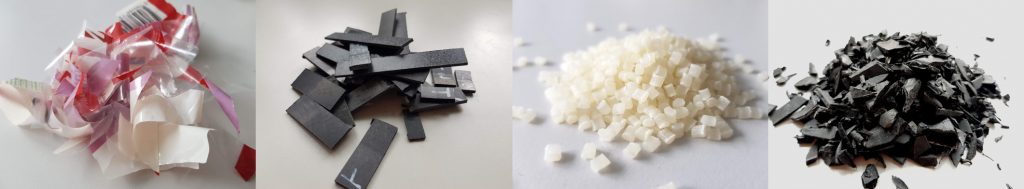

Using their reach into the relevant supply and value chains, partners such as Arkema, Bond Laminates, FARPLAS, and Amcor have secured numerous samples of both industrial scrap and post-consumer wastes and sent these back to a hub location at Fraunhofer IVV, the Fraunhofer Institute for Process Engineering and Packaging. Both laboratory characterization and experimentation on an existing CreaSolv® small-scale pilot plant is being used to parameterize the MultiCycle process, and to inform the design of a 25 kg/h scale, continuous pilot plant concept, including suitable monitoring systems for plastic waste composition tracking and process control being developed by IRIS Technology Group.

Trials at this stage will be dealing ultimately with representative, tailor-made samples of around 100 kg of targeted waste streams, which will be processed over multiple batches to allow testing of process stability and multiple use of recovered solvents. This will also enable the quality of recovered target polymers to be assessed and will provide samples for post-processing.