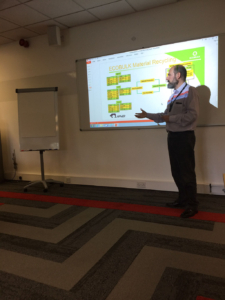

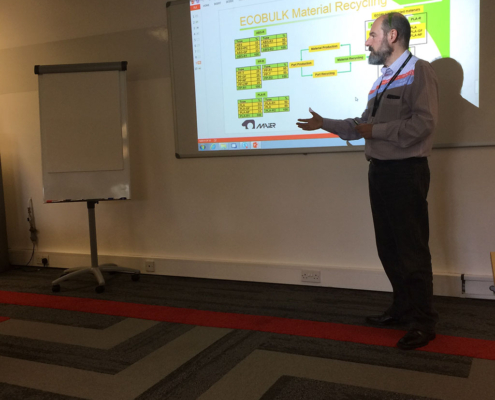

Two years of Ecobulk where celebrated last week in Coventry, historical home of the British automotive industry. The meeting was hosted by the new project partners Warwick and Coventry University at the Scarman Conference Centre. Both partners will be contributing through their demonstrations of the new prototypes in furniture and construction sectors, as well input on the design of circular value chains.

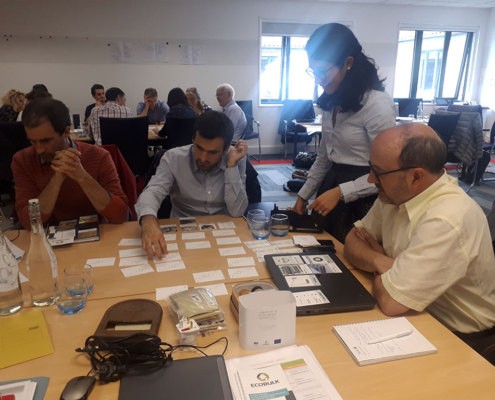

The main aim of the meeting was to put all the pieces of the puzzle together for each of the planned demonstrations. Several exciting new concepts have been developed by the partners in the past 2 years which we expect will enable new highly circular materials and products to be produced. But the Ecobulk project is a large-scale demonstration initiative, and so an integral part of the challenge is to fit all the newly developed partial solutions into a coherent, circular chain that is feasible – not only technically, or theoretically, but also economically, and practically.

Furniture Sector

Moretti will be demonstrating the use of its modular furniture design concept for students and universities. They will be exploring business models that include the option to lease the furniture to their users, and where possible, recondition and re-use the returned furniture. With research from KEAS and Akzo-Nobel, the percentage of re-cycled particle board used in production can be significantly increased to accommodate the return of used furniture into the production lines.

Construction Sector

Conenor has developed some interesting new WPC materials using ‘waste’ materials from diverse sources such as wind turbine blades, discarded furniture, and plastic pipes. These will be used in several demonstration sites to create appealing light outdoor constructions and furniture. The materials are 100% recyclable into the same material at the end of life. With careful design and selection of fasteners, the individual components will be easily taken apart and replaced when necessary.

Automotive Sector

In the automotive sector, MicroCab is designing a modular platform for their hydrogen powered cars that allows the controlled and timely replacement of auto parts that not only maintain the quality but also modernise the user experience during the lifetime of the vehicle. Meanwhile Maier and Fiat are working on using materials and processes for their interior car parts that can re-use the plastics being retrieved by TOMRA, AIMPLAS and Bellver from shredded vehicles.

More to Come Soon ….

With the prototypes and demonstrations almost ready, we will be updating soon the information about where you can see the Ecobulk products being tested all across Europe.